Home made SCT cooler

Home made SCT blow-through cooler

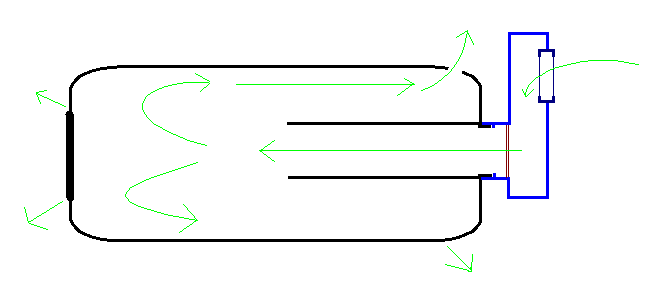

Instead of just causing air turbulence in the OTA I've decided to make a cooler that will push the air through the whole OTA. The air enters through the optical back and goes out through holes in the OTA and through holes after mounting screws by the primary mirror on top of the OTA (by the finder). This should be more efficient and reduce boundary layers around primary mirror:

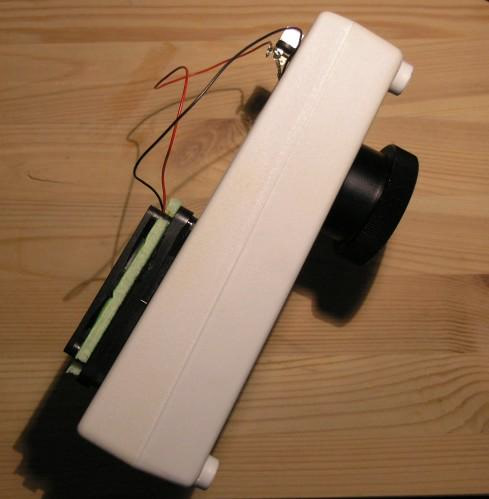

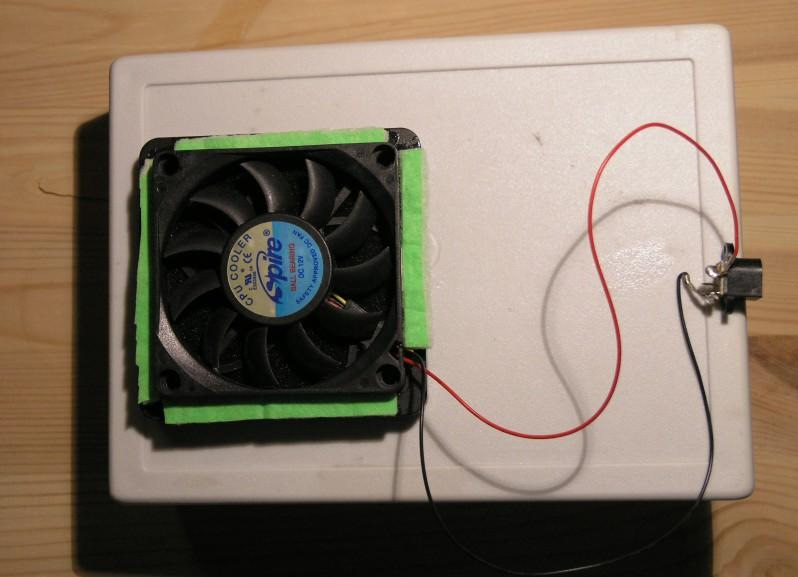

To make this cooler I've used 12V fan from a CPU cooling set, a standard plastic box for housing electronics (from an electronics shop), two fan covers with foam for catching bigger dust particles, and a SCT visualback to get an SCT thread that can be screwed to the SCT optical back. This cost only few Euro.

It's good to get fan covers in the same size as the fan you want to use. The fan must be quite fast to push air throug few filters:

The bad thing abot blowing air to the OTA is that we blow in also dust. To remove the dust we have to use filters. Foam filters won't cover smaller dust particles. I've used also a thin microfiber cloth before the visual back and two foam filters in the fan covers.

The 12V fan can be powered by a common AC adapter or a battery pack. You can solder matching connection plug for the version you want to get. The housing of the cooler must be hermetical from the inlet to the outlet - keeping the air pressure for the OTA. I used a standard plastic box that was designed to hold some custom electronics and hadn't any holes. I've cut on one side hole for the fan, and on the other side - hole for the SCT visual back. To hermetically connect everything I've used some plastic glues and standard "superglue" for connections with no gaps and holes. The result:

Comment article